使用安全模块

MpIO可以 像处理 灰色 I/O 模块一样处理安全模块 。 与 灰色 I/O模块 的 唯一区别 在于 "交叉链接",即安全模块与 SafeLOGIC 控制器之间的交叉引用,这些引用存储在安全模块的硬件配置中。

如果使用 MpIO 移动、添加或删除了安全模块,那么交叉链接就会过时。这可能导致导入过程中出现错误。可以在 MpIO 配置中使用 "删除未解决的交叉链路 "属性 来避免这些错误。如果将该属性设置为 "true",则所有过时的交叉链路都会在导入过程中自动删除。

MpIO不能修改 SafeLOGIC 控制器的程序或功能!如果修改了硬件配置,也必须确保 SafeLOGIC 控制器能够处理修改后的条件。

使用运动控制 (ACP10)

mapp IO 还可以将轴对象映射到特定驱动器。 导入文件的结构 部分 介绍了如何在导入文件中将轴对象连接到驱动器。可以在导入文件中定义轴对象位于哪个硬件位置。

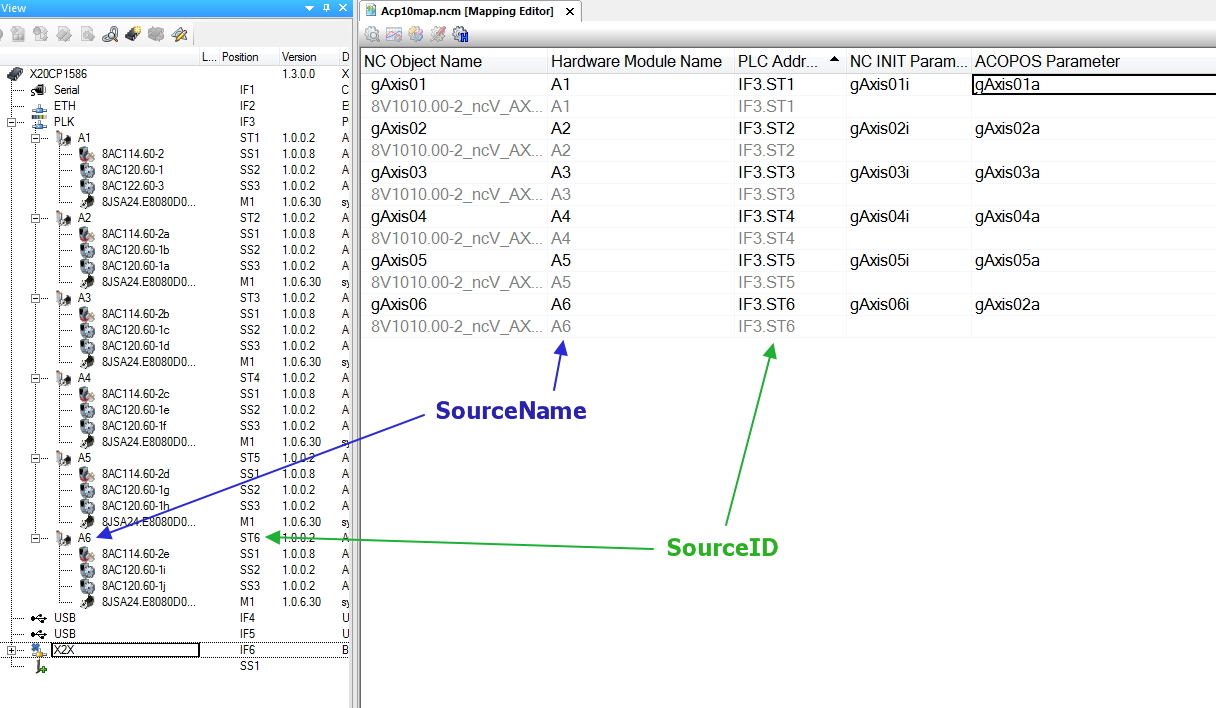

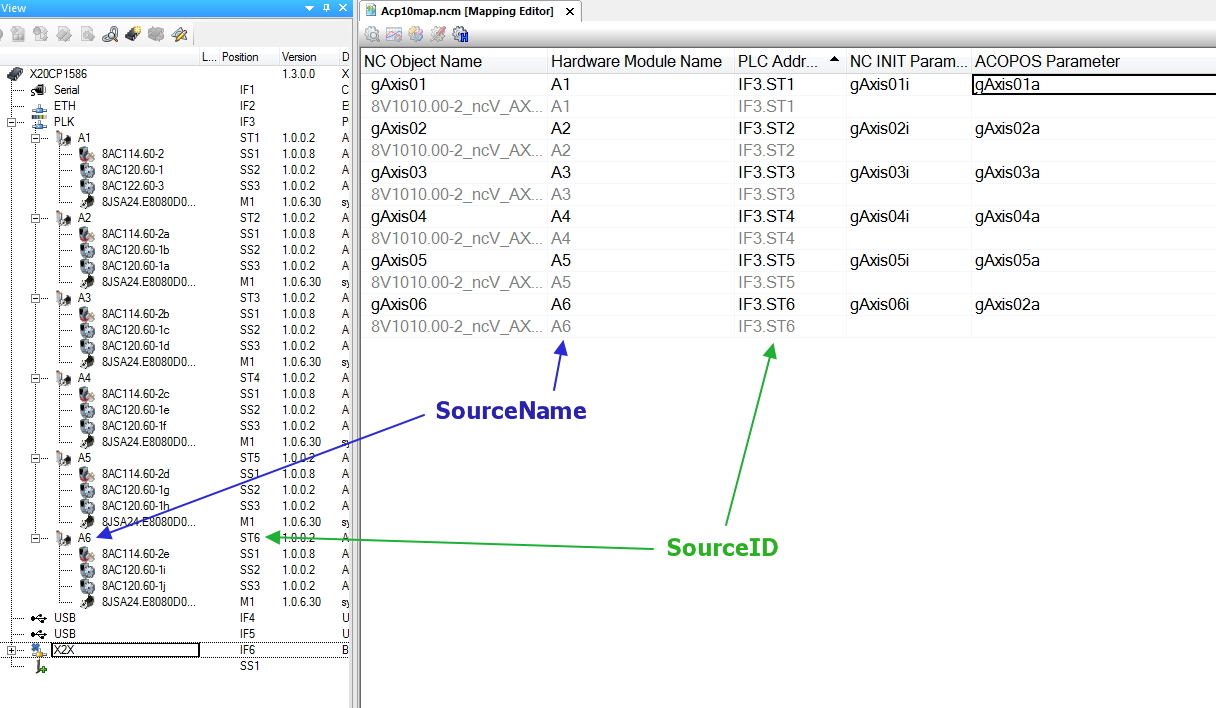

轴对象以及目标位置在硬件树中的位置在此更改。NC Init 参数模块和 ACOPOS 参数表不会被修改。这些将从源应用(由 导入文件中的SourceID 或 SourceName定义 )。

图片显示的是一个有 6 个轴的 NC 映射表。在导入过程中,轴 A2 和 A3 以及 A5 和 A6 应被替换掉。此外,客户配置中没有 A4 轴。相关导入文件如下

<IOCFG xmlns="http://www.br-automation.com/AR/IO" Version="2.0">

<Module ID="$root" Source="AR" SourceID="$root" />

<Module ID="IF3.ST1" Source="AR" SourceName="A1" >

<NcObject Name="gAxis01" Channel="1" />

</Module>

<Module ID="IF3.ST2" Source="AR" SourceName="A3" >

<NcObject Name="gAxis03" Channel="1" />

</Module>

<Module ID="IF3.ST3" Source="AR" SourceName="A2" >

<NcObject Name="gAxis02" Channel="1" />

</Module>

<Module ID="IF3.ST5" Source="AR" SourceID="IF3.ST6" >

<NcObject Name="gAxis06" Channel="1" />

</Module>

<Module ID="IF3.ST6" Source="AR" SourceID="IF3.ST5" >

<NcObject Name="gAxis05" Channel="1" />

</Module>

</IOCFG>

•在导入文件中,轴 A1 的接口地址 IF3.ST1(节点号为 1 的 POWERLINK 接口)保持不变。

•轴 A2 和 A3 在 POWERLINK 接口上交换了位置。为 轴 A3 的 模块 ID指定了地址 IF3.ST2 , 该 模块 ID 由 SourceName 标识 。这将改变驱动器在硬件树中的位置。轴 A3 使用的 NC Init 参数模块和 ACOPOS 参数表不会更改。

•轴 A2 则相反 ,其 Module ID 被定义为 IF3.ST3。

•轴 A4 被完全省略,可能是因为最终用户在购买机器时不需要某个选项。

•轴 A5 和 A6 也在 POWERLINK 接口上交换位置。与 A2 和 A3 的交换不同之处在于,轴的标识是 SourceID 而不是 SourceName, 换句话说,是硬件配置中的原始地址。

使用第三方硬件

mapp IO 对第三方硬件的处理方式与 B&R 模块相同。如果使用 AS 配置了硬件,则可以通过导入文件修改第三方硬件的 I/O 映射和配置。

第三方硬件始终可 按如下方式指定:

<Module ID="IF6.ST2" Source="AR" SourceName="My3rdPartyHardware" >

<LN ID="DigitalOutput01" DPName="doOutput1" />

</Module>

Working with safety modules

Safety modules are handled by MpIO like gray I/O modules. The only difference to the gray I/O modules has to do with the "crosslinks", i.e. cross-references between the safety module and the SafeLOGIC controller that are stored in the hardware configuration of the safety modules.

If a safety module is moved, added or deleted using MpIO, then the crosslinks are obsolete. This can cause errors during import. Property "Remove unresolved crosslinks" can be used in the MpIO configuration to avoid these errors. If this property is set to TRUE, then all outdated crosslinks are automatically deleted during import.

MpIO cannot modify the program or functionality of the SafeLOGIC controller! If the hardware configuration is modified, it must also be ensured that the SafeLOGIC controller can handle the modified conditions.

Working with motion control (ACP10)

mapp IO also makes it possible to map axis objects to a specific drive. Section Structure of the import file describes how to connect an axis object to a drive in the import file. Which axis object is located at which hardware position can be defined in the import file.

The axis object as well as the target position in the hardware tree are changed here. The NC Init parameter module and ACOPOS parameter tables are not modified. These are applied from the source (defined by SourceID or SourceName in the import file).

The image shows an NC mapping table with 6 axes. During import, axes A2 and A3 as well as A5 and A6 should be switched out. In addition, axis A4 does not exist in the configuration for the customer. The associated import file could look like this:

<IOCFG xmlns="http://www.br-automation.com/AR/IO" Version="2.0">

<Module ID="$root" Source="AR" SourceID="$root" />

<Module ID="IF3.ST1" Source="AR" SourceName="A1" >

<NcObject Name="gAxis01" Channel="1" />

</Module>

<Module ID="IF3.ST2" Source="AR" SourceName="A3" >

<NcObject Name="gAxis03" Channel="1" />

</Module>

<Module ID="IF3.ST3" Source="AR" SourceName="A2" >

<NcObject Name="gAxis02" Channel="1" />

</Module>

<Module ID="IF3.ST5" Source="AR" SourceID="IF3.ST6" >

<NcObject Name="gAxis06" Channel="1" />

</Module>

<Module ID="IF3.ST6" Source="AR" SourceID="IF3.ST5" >

<NcObject Name="gAxis05" Channel="1" />

</Module>

</IOCFG>

•In the import file, axis A1 remains unchanged at interface address IF3.ST1, the POWERLINK interface with node number 1.

•Axes A2 and A3 exchange their positions on the POWERLINK interface. Address IF3.ST2 is specified for Module ID for axis A3, which is identified by SourceName. This changes the position of the drive in the hardware tree. The NC Init parameter module used for axis A3 and the ACOPOS parameter table are not changed.

•This is reversed for axis A2, where Module ID is defined as IF3.ST3.

•Axis A4 is omitted entirely, possibly because the end customer does not need a certain option when buying the machine.

•Axes A5 and A6 also exchange their positions on the POWERLINK interface. The difference with the exchange of A2 and A3 is that the axes are identified by SourceID instead of SourceName – in other words, the original address in the hardware configuration.

Working with 3rd-party hardware

mapp IO treats 3rd-party hardware in the same way as B&R modules. If the hardware is configured using Automation Studio, then the I/O mapping and configuration of the 3rd-party hardware can be modified with the import file.

3rd-party hardware can always be specified as follows:

<Module ID="IF6.ST2" Source="AR" SourceName="My3rdPartyHardware" >

<LN ID="DigitalOutput01" DPName="doOutput1" />

</Module>