mapp Services V5.16

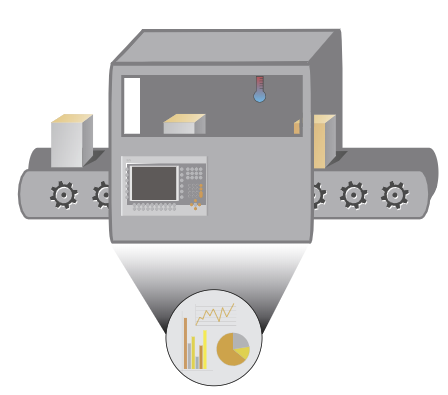

This section explains the basic concept of mapp OEE.

Statistical information (overall equipment effectiveness) of a machine is collected and evaluated using mapp OEE. This evaluation can be used to optimize the machine process. The goal is to deliver larger quantities, to improve the quality of the products and to gain an overview of the machine downtimes, for example. The overall equipment effectiveness values serve as the basis for the evaluation. For this purpose, the machine's runtime, downtime, number of products produced, and much more must be known exactly.

Defining machine times

When the machine is active and producing products, this is known as "uptime". If the machine comes to a standstill, this can be scheduled or unscheduled machine downtime. Scheduled downtimes are defined via the MpOeeCore configuration. Fixed times are defined. A scheduled downtime can be used for a break, for example.

Unscheduled downtime for the machine can also be specified via input parameter "Downtime" on MpOeeCore. An unscheduled standstill can be triggered by a defective module or faulty conveyor belt, for example.

The reason for the unscheduled downtime is defined using "DowntimeReason" on MpOeeCore. This can be "Defect module" or "Safety door opened", for example.

For additional information about this, see here.

Quantities

The number of products produced by the machine is calculated by the application and transferred to mapp OEE. The number of products or rejects produced is defined via "PieceCounter" or "RejectCounter" on MpOeeCore. These values are also included in the overall equipment effectiveness values. For additional information about this, see here.

Shifts

A production day can be divided into shifts in mapp OEE. Depending on how the production day was configured, other overall equipment effectiveness values may be displayed for the shifts.

Overall equipment effectiveness

The overall equipment effectiveness values are based on the defined times, units produced, etc. These can be seen on the output parameters of MpOeeCore.

For information about which parameters make up the overall equipment effectiveness values and how they are calculated, see section Calculating overall equipment effectiveness.