mapp Services V5.16

This function block forms the core of overall equipment effectiveness (OEE management) and requires the MpLink of an MpOeeCore configuration.

Defining the runtime of the machine

As soon as MpOeeCore is active, OEE data is collected for the current shift. If not defined otherwise, the time that MpOeeCore is active is referred to as "Uptime". This means that the machine is productive during this time.

If the machine encounters (unscheduled) stoppage, then this must be specified using input "Downtime". As long as this input is active, the time is calculated as "Downtime". The machine is unproductive during this time. The reason for the unscheduled downtime should be specified using input "DowntimeReason", e.g. "Conveyor belt error".

Number of products

Input "PieceCounter" specifies the total number of products manufactured since the machine was started. When the machine is started, the counter starts at 0 and begins counting all products. Input "RejectCounter" is used to count all rejected products. The products are not counted by MpOeeCore. MpOeeCore simply assigns the correct data to the corresponding shift and utilizes the data in the OEE statistics. Warning "Data inconsistent" is specified in the Logger if a value that is smaller than the preceding one is specified at "RejectCounter" or "PieceCounter". If the machine comes to a standstill while other products are produced, e.g. because the machine cannot come to an abrupt stop, these are also included in the OEE data.

Resetting the buffer

Using command "Reset = TRUE", the data in the internal buffer is reset. This means that all job data, statistic data and timeline data collected up to this point will be deleted. Data provided by the user, such as the units produced, are not deleted.

Overall equipment effectiveness

Parameters for calculating overall equipment effectiveness

The required value is specified in the parameter structure; this is important for calculating the overall equipment effectiveness:

•IdealCycleTime: IdealCycleTime specifies the ideal cycle time for creating a product, e.g. 2 minutes. For this, it is important to know how fast a product can be produced by the machine. The user defines the "ideal" cycle time. This means that the machine is still capable of production if the time is faster or slower.

Overall equipment effectiveness

The overall equipment effectiveness is indicated on the function block's output parameters. For information about these parameters and how they are calculated, see section Calculating overall equipment effectiveness. Further parameters are available in the information structure of the function block.

Evaluation of the overall system effectiveness

It is up to the user to evaluate the values. The export function can be used to create a detailed overview of the overall equipment effectiveness of the machine. This can be used to analyze how the productivity of the machine can be increased.

If several unplanned downtimes occur on the machine, for example, it is necessary to find out how these can be better avoided in order not to negatively influence the productivity of the machine. If many bad products ("RejectCounter") are produced, the manufacturing process of the product must be analyzed more precisely, etc.

Export

The "Export" command exports a file with the current data from memory. Output "ExportDone" indicates that the export was carried out successfully. An export can include the statistics of the current shift as well as the timeline with the last events (state changes).

Timeline

The timeline displays all events that occur during a shift. Each time an event occurs, an entry is created in the timeline. In the event of downtime, for example, its duration, the shift in which it occurred, etc. are entered. A running machine is considered uptime, which is also recorded as an event. This could look like this:

Shift statistics

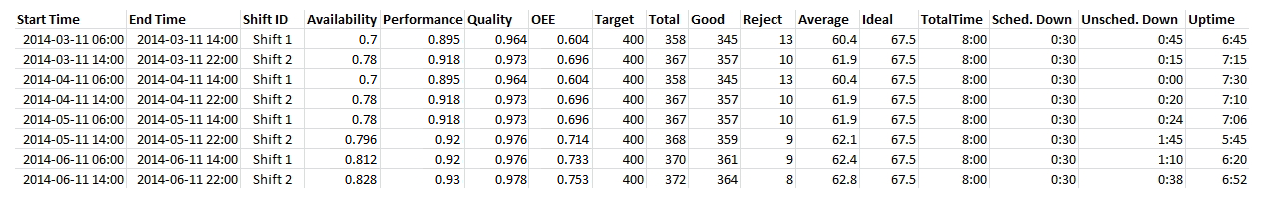

An entry is created for each shift in the shift statistics. All OEE-relevant data for the respective shift is included, e.g. OEE value, performance, availability, starting/ending point of the shift, etc. This looks something like this:

Whether all data (timeline and shift statistics) or only a subset should be exported can be defined in the configuration.