mapp Services V5.16

This function block forms the core for calculating asset intensity and requires the MpLink of an MpAssetIntCore configuration. In order to map the asset intensity, the shift model or jobs of the machine must be known. For additional information, see section Shifts and jobs.

Defining the runtime of the machine

As soon as MpAssetIntCore is active, statistical data is collected for the current shift or job. If not defined otherwise, the time that MpAssetIntCore is active is referred to as "Uptime". This means that the machine is productive during this time.

In addition to "uptime", the machine can be at a scheduled or unscheduled standstill. Scheduled standstill times are defined in the MpAssetIntCore configuration. If for some reason the scheduled downtime must start earlier or later, it can still be specified to MpAssetIntCore via input parameter "Downtime".

Unscheduled downtime can also be defined via "Downtime". The reason for the downtime is defined using DowntimeReason. This could be "Defective conveyor belt" or "Safety gate open", for example.

Number of products

Input "PieceCounter" specifies the total number of products manufactured since the machine was started. When the machine is started, the counter starts at 0 and begins counting all products. Input "RejectCounter" is used to count all rejected products. The products are not counted by MpAssetIntCore. MpAssetIntCore assigns the correct data to the corresponding job or shift and uses the data in the statistics. It is important to note that a job must always run during a shift. If the number of pieces is increased during a job and a shift is not currently in progress, the products are not included in the asset intensity calculation. The number of products is directly linked to the production rates. If the number of products does not increase steadily or increases only slowly or not at all, this has a negative effect on the current production rate ("CurrentProductionRate"), for example. Warning "Data inconsistent" is specified in the Logger if a value that is smaller than the preceding one is specified at "RejectCounter" or "PieceCounter". If the machine transitions to a standstill while further products are produced, for example because the machine cannot stop abruptly, these are also included in the AssetInt data.

Resetting the buffer

Using command "Reset = TRUE", the data in the internal buffer is reset. This means that all job data, statistic data and timeline data collected up to this point will be deleted. Data provided by the user, such as the units produced, are not deleted.

Asset intensity

Parameters for calculating asset intensity

Structure Parameter specifies all the values that are needed to calculate asset intensity. This includes:

•NominalProductionRate: Specifies the nominal production rate of the machine, e.g. 5000 products/hour. For more information, see section Calculating asset intensity.

•Job: If production is represented by jobs, the job name can be defined via this parameter (e.g. 2l bottle, 1l bottle). For more information, see section Shifts and jobs.

•CurrentUser: The currently logged-in user can be specified here.

•AdditionalData: "AdditionalData" can be used to add additional information to the shift/job.

Asset intensity

The asset intensity is indicated on the function block's output parameters. For an explanation of these parameters and how they are calculated, see section Calculating asset intensity.

Depending on whether the production day is divided into shifts and/or jobs, additional asset intensity values are located in the Info structure.

Evaluating the asset intensity

It is up to the user to evaluate the asset intensity values. The export function can be used to create a detailed overview of the asset intensity of the machine. This can be used to analyze how the productivity of the machine can be increased.

If several unplanned downtimes occur on the machine, for example, it is necessary to find out how these can be better avoided in order not to negatively influence the productivity of the machine. If many bad products ("RejectCounter") are produced, the manufacturing process of the product must be analyzed more precisely, etc.

Export

The "Export" command exports a file with the current data from memory. Output "ExportDone" indicates that the export was carried out successfully. An export can include the statistics of the current job or shift as well as the timeline with the last events (state changes).

An entry is always created in the exported lists as soon as a shift has been completed or as soon as a job change has been performed. If a job change is performed during a shift, the entry contains the data since the beginning of the shift until the time of the job change. If the shift has ended, the data from the time of the shift change to the end of the shift is listed.

Timeline

The timeline displays all events that occur during a job or shift. This includes planned as well as unplanned downtimes or the operating time of the machine, for example. The list could look something like this:

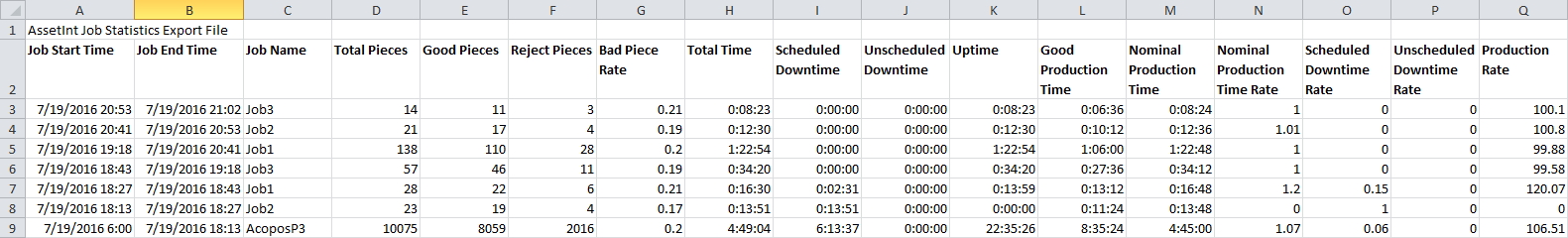

Job statistics

All relevant data for a job is displayed in the job statistics, such as the start time of a job, the number of pieces produced, etc. This could look something like this:

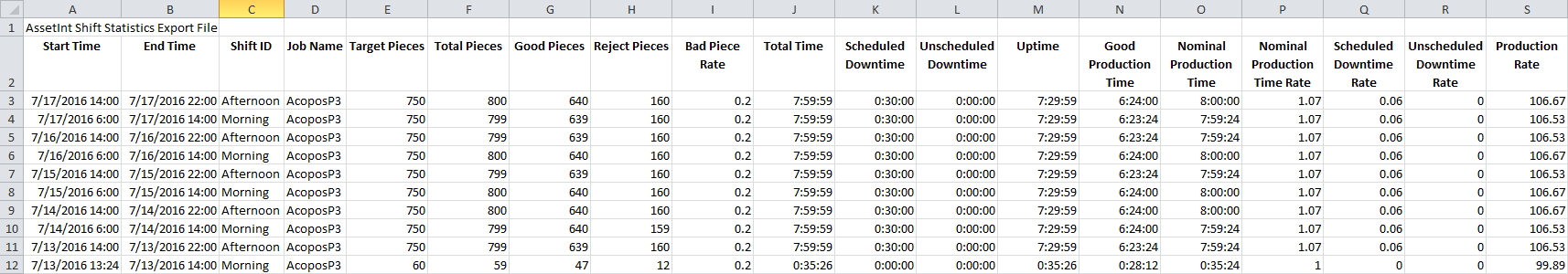

Shift statistics

The shift statistics contain all relevant data of a shift, such as the start and end times of a shift. This could look like this:

Whether all data (timeline and job statistics) or only a subset should be exported can be defined in the configuration.