mapp Services V5.16

This section explains the individual asset intensity values and how they are calculated. The parameters can be viewed with respect to the currently running shift or job.

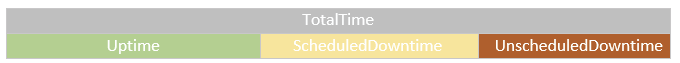

TotalTime, Uptime, ScheduledDowntime, UnscheduledDowntime

As explained in section Basic concept, times must be defined in a machine. These can be divided as follows:

•Uptime: Uptime is the time during which the machine actively produces products.

•ScheduledDowntime: ScheduledDowntime refers to a machine's scheduled downtime. This can be used for scheduled maintenance work on the machine or breaks, for example. Scheduled downtimes are defined in the MpAssetIntCore configuration. Fixed times are defined. If for some reason the scheduled downtime must start earlier or later, it can still be specified via input parameter "Downtime = mpASSETINT_SCHEDULED_DOWNTIME" on MpAssetIntCore. The reason for the standstill is defined via "DowntimeReason" on MpAssetIntCore.

•UnscheduledDowntime: UnscheduledDowntime refers to an unscheduled downtime on the machine. This can be triggered by a defective module or faulty conveyor belt, for example. The unscheduled downtime is specified via "Downtime = mpASSETINT_UNSCHEDULED_DOWNTIME" on MpAssetIntCore. The reason for the standstill is defined via "DowntimeReason" on MpAssetIntCore.

•TotalTime: The total runtime ("TotalTime") of the machine is composed of the "Uptime" and scheduled/unscheduled downtime.

NominalProductionRate

Parameter "NominalProductionRate" is specified on MpAssetIntCore under "Parameters".

NominalProductionRate specifies the nominal production rate of the machine, e.g. 5000 products/hour. Here, it is important to know many products the machine can produce per hour at nominal speed. The user must know at what speed the products can be produced. The user defines the "normal" speed. This means that the machine is still able to produce products at higher and slower speeds.

TotalPieces, GoodPieces, RejectedPieces, TargetPieces, BadPieceRate

In order to calculate the asset intensity, the exact quantities of the machine must be known. For this, parameters "PieceCounter" and "RejectedCounter" must be specified on MpAssetIntCore. These two parameters must be calculated in the application and specified to the function block.

The following parameters can be calculated from "PieceCounter" and "RejectedCounter". These parameters can be obtained with respect to the current shift/job. When starting a new shift or job, the parameters listed below are reset to 0.

•TotalPieces: TotalPieces returns the total quantity of products produced.

•RejectedPieces: Defective products may occur during production. The parameter returns the number of rejected products.

•GoodPieces: GoodPieces are products that are produced error-free or that meet the quality requirements. This is calculated as follows:

TotalPieces - RejectedPieces

•BadPieceRate: BadPieceRate specifies the rate of bad products. The parameter is calculated as follows:

RejectedPieces / TotalPieces

•TargetPieces: TargetPieces specifies the target quantity of products to be produced by the machine at nominal speed. The parameter is calculated as follows:

TotalTime * NominalProductionRate

GoodProductionTime, NominalProductionTime

•GoodProductionTime: "GoodProductionTime" displays how long the machine would theoretically have to run to produce the current number of "GoodPieces" at nominal speed. The parameter is calculated as follows:

GoodPieces* (3600 / NominalProductionRate)

•NominalProductionTime: "NominalProductionTime" displays how long the machine would theoretically have to run to produce the current number of "TotalPieces" at nominal speed. The parameter is calculated as follows:

TotalPieces * (3600 / NominalProductionRate)

ScheduledDowntimeRate, UnscheduledDowntimeRate, NominalProductionTimeRate, CurrentProductionRate, IdealProductionRate

Some periods of asset intensity are specified as a percentage. These parameters refer to the total runtime of the machine, i.e. from the time MpAssetIntCore was enabled. This means that this parameter does not refer to the current shift/job.

This data can only be set to 0 using a reset command on MpAssetIntCore. The data is retained even if function block MpAssetIntCore is disable and enabled again.

These can be divided into the following parameters:

•ScheduledDowntimeRate: ScheduledDowntimeRate specifies the percentage of the total runtime (TotalTime) that the machine spent in scheduled downtime. This parameter is calculated as follows.

ScheduledDowntime / TotalTime

•UnscheduledDowntimeRate: UnscheduledDowntimeRate specifies the percentage of the total runtime (TotalTime) the machine spent in unscheduled downtime. The parameter is calculated as follows:

UnscheduledDowntime / TotalTime

•NominalProductionTimeRate: NominalProductionTimeRate specifies the production time rate at machine's nominal speed. The parameter is calculated as follows:

NominalProductionTime / Uptime

•CurrentProductionRate: CurrentProductionRate returns the current production rate of the machine. The parameter is calculated as follows:

TotalPieces / TotalTime

•IdealProductionRate: Defines the ideal production time rate of the machine. The value specifies how many products can be produced at the machine's nominal speed from the time a shift starts. The parameter is calculated as follows:

NominalProductionTime / TotalTime