mapp Services V5.16

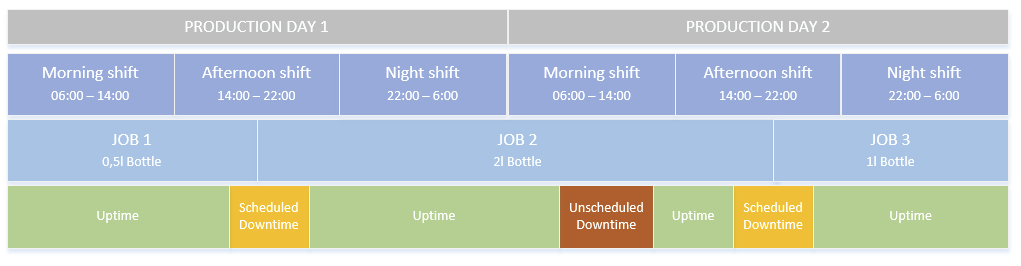

A production day can be divided into either shifts or jobs.

In our example, a production day is divided into 3 shifts: Early shift, late shift and night shift. The jobs are not bound to the shifts and can be defined independently.

3 different jobs were defined. The production of 0.5, 1 and 2 liter bottles.

It is possible to take a closer look at the asset intensity for each shift or job.

Dividing up shifts

A machine's shift model is defined in the Configuration of MpAssetInt. This division could look something like this:

The time is specified in microseconds starting at 12:00 AM. This means the morning shift starts at 6:00 AM and continues until 2:00 PM.

Scheduled downtimes can also be defined for each shift in which break times can be specified, for example. In this example, a downtime was scheduled for the afternoon shift to perform maintenance work on the machine. In addition, unscheduled downtimes can also occur; these can be triggered by a problem on the conveyor belt, for example.

It is important to note that on the first day of production, the asset intensity of the morning shift will vary greatly from the afternoon shift since the machine was in scheduled/unscheduled standstill. The production rate of the machine in the morning shift will be much higher than in the afternoon shift, for example.

Asset intensity data can be viewed for each shift. These can be viewed in the info structure of MpAssetIntCore under MpAssetIntShiftStatisticsType.

Dividing up jobs

A job refers to the production of a specific product, such as a 0.5 liter plastic bottle. A job can be independent of the shift schedule but must run during a shift. This means that a job can run during two or even more shifts.

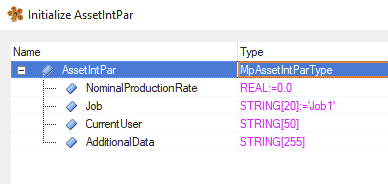

At runtime, the job is specified via the parameter structure of MpAssetIntCore. This means that the user can define when a job should be started and ended.

Assume that 6000 0.5 liter bottles should be produced. The production of these 6000 bottles runs from 6:00 AM to 3:30 PM. After that, 2 liter bottles should be produced. In between, the machine is at a scheduled/unscheduled standstill due to maintenance work. The production of the 2 liter bottles then begins.

If asset intensity is now evaluated for the morning and afternoon shifts, these will vary greatly since the machine was in scheduled standstill. It therefore makes sense to analyze the values with respect to the job. These can be viewed in the info structure of MpAssetIntCore under MpAssetIntJobStatisticsType.