mapp Services V5.16

Requirement

A machine transports products to a conveyor belt. The production manager wants to monitor the energy consumption of his machine. For this reason, the energy data of the conveyor belt must be displayed in an HMI application. It should be possible to export the collected data to a USB flash drive. The production manager is therefore able to analyze data and optimize processes accordingly.

The energy consumption of an axis can only be calculated if the drive system being used has a power supply module! Such a module uses an ACOPOSmulti drive, for example.

This use case only works in combination with the ACP10/ARNC0 Technology Package.

Solution

•Component list

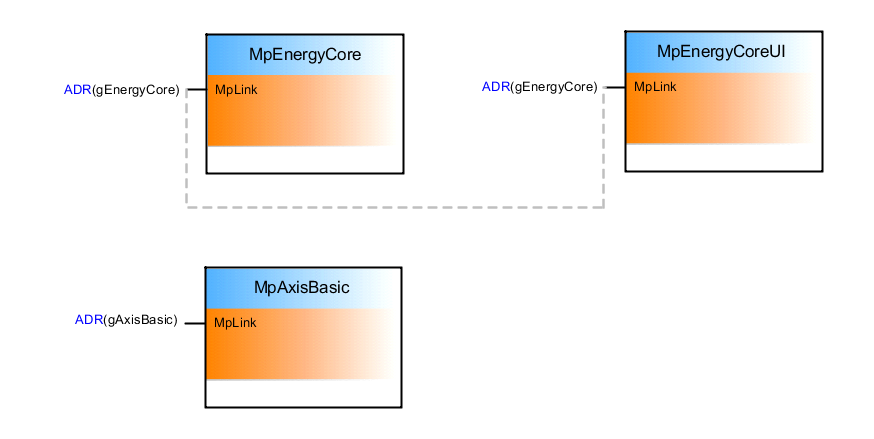

•MpAxisBasic (own MpLink): Controls the axis

•MpEnergyCore (own MpLink): Collects energy data.

•MpEnergyCoreUI (MpLink from MpEnergyCore): Contains all necessary parameters and structures for establishing a connection to an HMI application and displaying the collected energy data in graphic and table form.

Connection diagram

Configuration

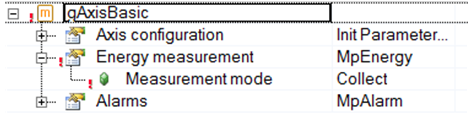

The "MpAxisBasic Default" and "MpEnergyCore Default" configurations are added.

"Collect" mode must be selected under "Energy measurement" in the axis configuration. In this way, MpEnergyCore automatically collects the energy data of an axis.

Using the mapp components

The MpAxisBasic component is added to control the axis; MpEnergyCore is added to collect energy data. For information about establishing a connection to an HMI application using MpEnergyCoreUI, see section VC4 templates.

The components are connected to one another as depicted in "Connection diagram". All components are then configured.

MpEnergyCore now collects the energy data of the axis during runtime. The command "MpEnergyCore.Export = TRUE" exports the collected data to a specified data storage device such as a USB flash drive.