mapp Services V5.16

Requirement

A machine manufacturer builds injection molding machines. End customers regularly request the flexible integration of additional sensors and/or actuators into the machine process.

An end customer would like to transport new products away on a conveyor belt after they have been ejected, for example. Another would like an additional traffic light to be installed on the machine in order to quickly see whether the machine has stopped or is still running.

Mechanical manufacturer: Preparation

The machine manufacturer uses a combination of additional hardware and software. The hardware consists of an additional digital input module and a digital output module. mapp CodeBox is integrated into the software of the injection molding machine.

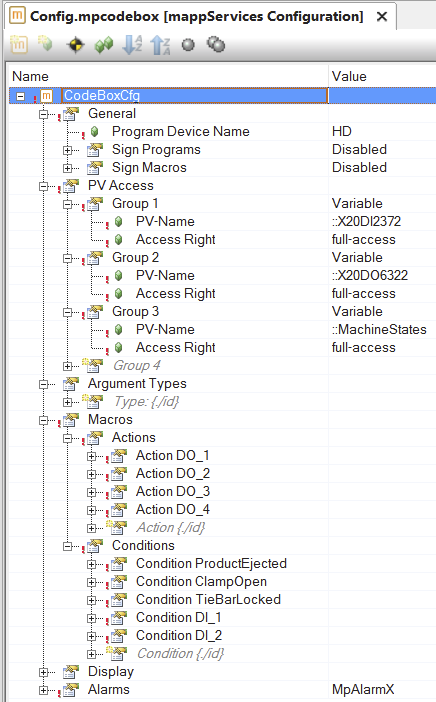

MpCodeBox configuration

Various actions and conditions that can be connected as needed are an example of how the end customer is able to influence the process self-reliantly. This includes actions such as checking the states on the additional digital input module ("DI_1", etc.) and enabling the additional outputs on the digital output module ("DO_1", etc.), but also various predefined states of the machine such as "ClampOpen", "TieBarLocked" and "ProductEjected".

For this, the MpCodeBox configuration must be added. "PV access" defines that the end customer only has access to the structures that are connected to the digital input or output module. Different machine states can also be accessed.

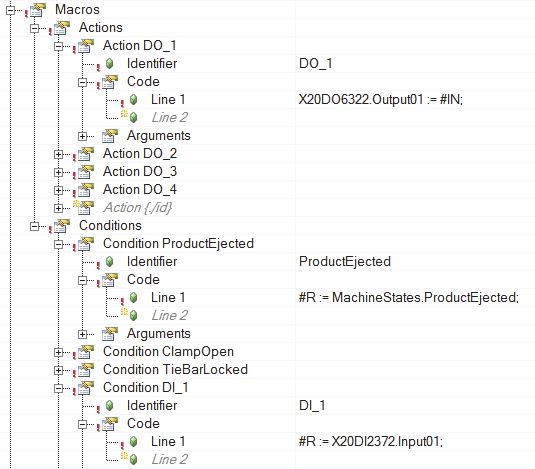

The actions and conditions mentioned above can be defined in section "Macros".

For more information about creating actions and conditions, see here.

Fig.: MpCodeBox configuration

Fig.: Definition of macros

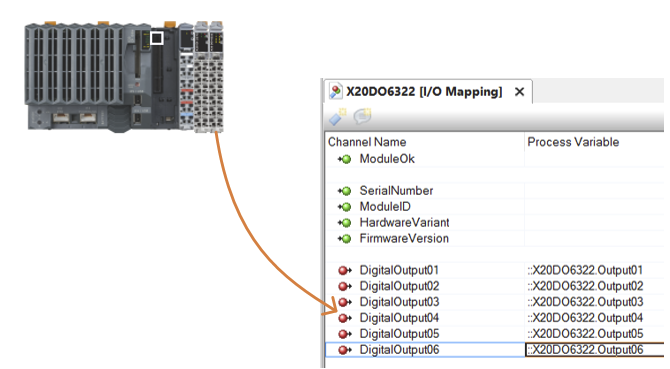

Fig.: IO mapping of the output module

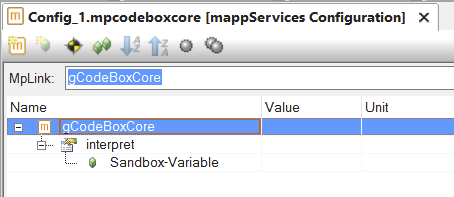

MpCodeBoxCore configuration

Each MpCodeBox instance requires a MpCodeBoxCore configuration that provides the mapp Link needed for programming. The mapp Link establishes a connection between application and configuration.

Customizing the application

In order to start programs that the end customer creates at runtime, function block MpCodeBoxCore is added.

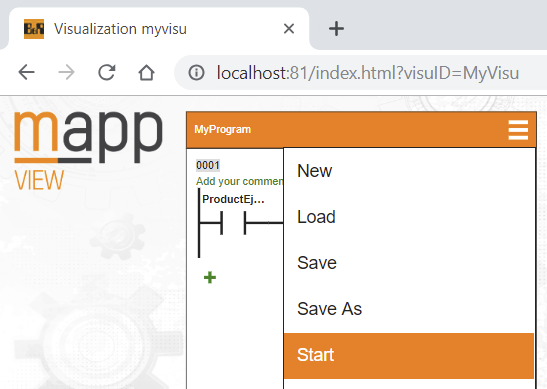

mapp View HMI application

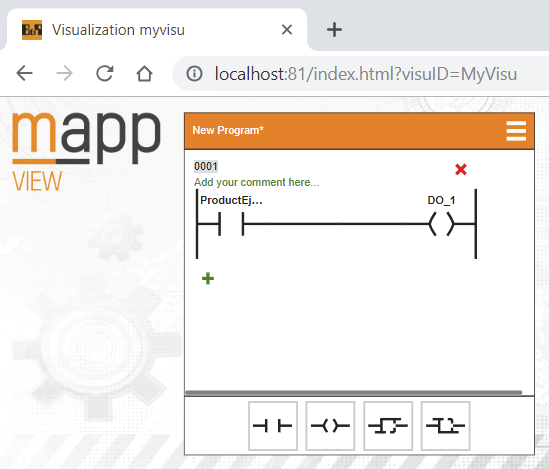

A mapp View HMI application has already been created for the injection molding machine. So that the end customer can adjust the program at runtime, widget "LadderEditor" is added and configured. For more information, see section Example configuration.

All preparations required by the machine-builder have been completed.

End customer: Use

The end customer is now able to influence his machine process via the HMI application.

For example, a conveyor belt should be activated via output 1 of the digital output module when a product has been ejected:

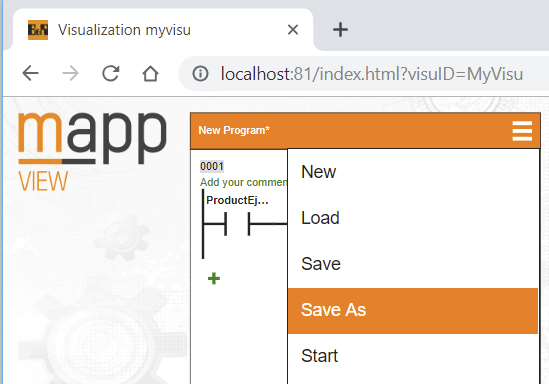

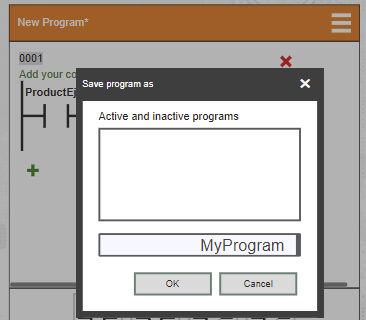

To save the created program, open the menu in the title bar and select "Save as".

Any name can be entered for the program:

The program can be started via the menu of the title bar: